4 Tips for Increasing Capacity for Jaw Crusher

Nov 07, 2024Jaw crushers are usually used for the primary crushing stage in production lines, and their output directly affects the capacity of the entire production line. Meanwhile, we can reduce equipment idle by increasing output per unit time, thus reducing energy consumption and labor costs, finally improving the overall efficiency. Today, we are glad to share with you a few tips for increasing capacity for Jaw crusher.

1. Optimize the feed size, STUCK NO MORE!

Choose dry and low mud materials to reduce adhesion and clogging in the crushing process and improve crushing efficiency.

Control the feed size less than 85% short side of the crusher inlet size, or oversize material will easy to be stuck at the opening of jaw crusher.

2. Control the feed rate, avoid overfeed clogging

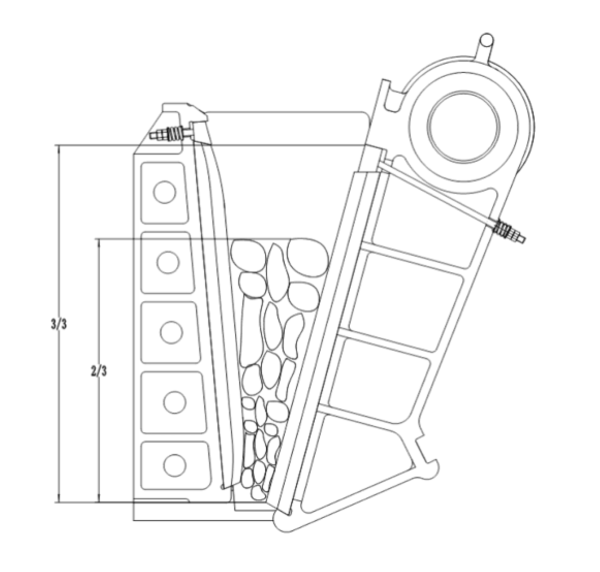

Therefore, we should strictly control the feeding rate,at the same time, keep a constant feeding rate by adjusting the amplitude of the feeder (within the feeder amplitude range) according to the output demand of the production line. Normally, when the feeding rate is up to 2/3 of the crushing chamber,the efficiency is the highest.

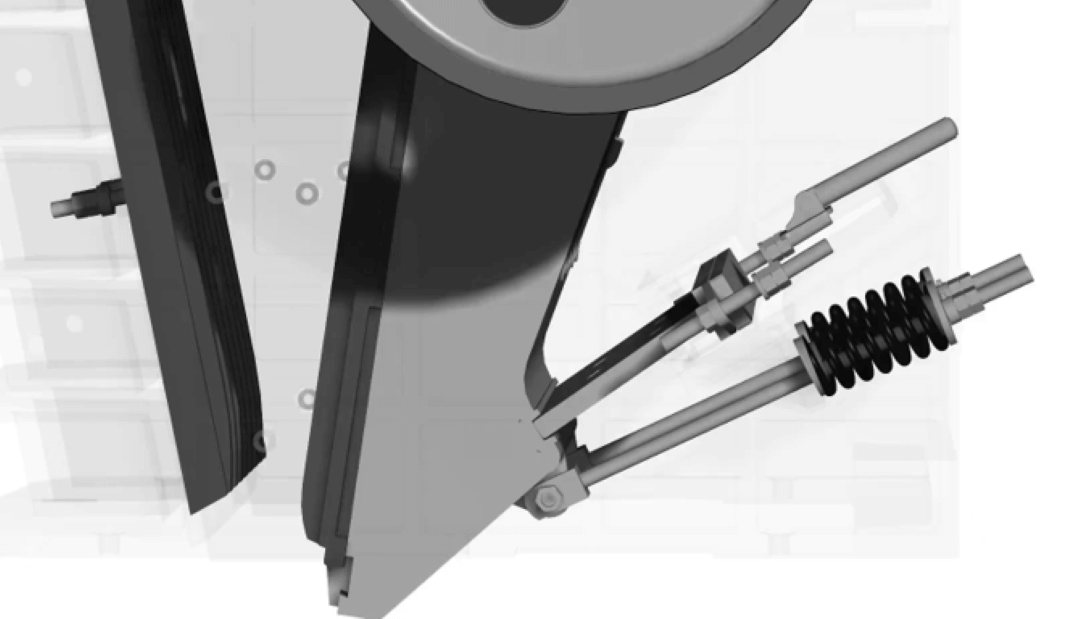

Meanwhile,we should also avoid the material directly impact the moving jaw when feeding,and prevent the head of the moving jaw when feeding, and prevent the head of the moving jaw to be damaged. Additionally, adjusting feed angle ensure feeding smooth.

3. Adjust equipment properly, improve processing capacity

Increasing the eccentric shaft speed appropriately is good for improving material crushing efficiency. But it should be noted that excessive speed may make materials not be discharged in time, causing material blockage and reducing production capacity.

4. Regular maintenance equipment

High quality lubrication is the key to ensure the performance and service life of bearings. In daily equipment operation, the bearings of jaw crushers should be regularly lubricated and maintained to ensure their normal operation.

Take care of your jaw crushers anytime, anywhere. For more information, you can also contact your local dealer or Borgers service team.