How to Ensure Multi Cone Full Capacity

Sep 19, 2024Hello! As one of the key equipment in the production line, the efficiency of the multi-cylinder cone crusher directly determines the speed and efficiency of the subsequent processing steps. It is important to focus on improving the efficiency of the multi-cylinder cone crusher in daily operation, as this can significantly enhance the overall efficiency and production capacity of the entire production line. Today, we would like to share a few tips for improving the efficiency of the equipment.

Optimize Operation:

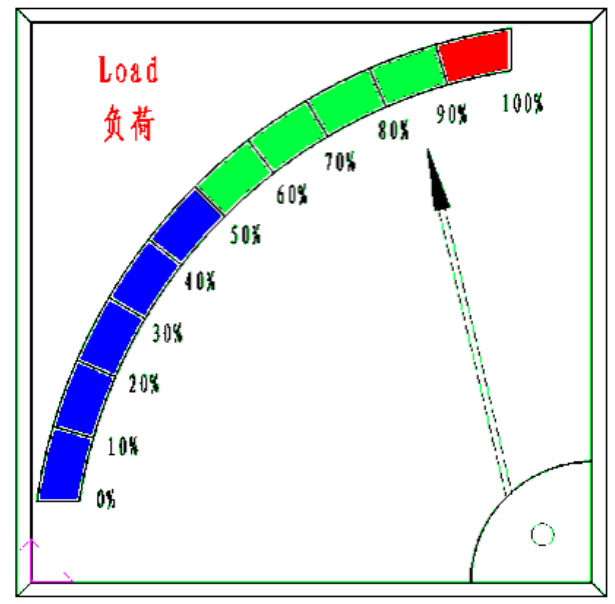

Power Control:

To increase power, it is important to have sufficient feed rather than reducing the discharge opening. A smaller discharge opening may increase power but reduce throughput. In the operation of the cone crusher, power should be strictly controlled. The optimal power range is around 70-80% for medium crushing and within 80-90% for fine crushing. During operation, the power of the crusher should be adjusted based on the variation in feed rate, ensuring a stable driving power and preventing operation beyond the rated.

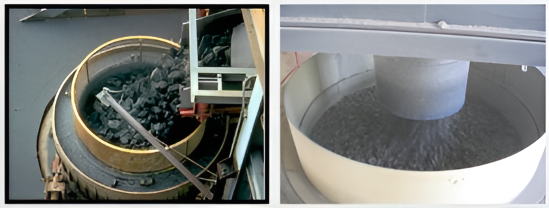

Feed Level Control:

Maintaining a high level of material in the crushing chamber of the cone crusher is recommended. It is advisable to have a material height exceeding 300mm above the distribution plate to achieve "full chamber" operation and enhance crushing efficiency. The feeding should be filled completely and dropped vertically onto the distribute.

Adjust Closed Side Setting:

Keep the parameters of the close-side discharge port unchanged to maintain a consistent product size. According to production needs, adjust the size of the discharge port appropriately to match the discharge ports of intermediate and fine crushing, thereby improving the overall capacity of the crushing system.

Improving feeding conditions:

Regular mainternace of equipment:

In addition to optimizing operations, it is important to regularly maintain the crusher, inspect the wear condition of each component, and promptly replace severely worn parts to ensure that the equipment is in good condition. When the crusher is blocked or shut down with material still inside, it is necessary to perform chamber cleaning before restarting the crusher to keep the crushing chamber unobstructed.

Optimizing the production process:

Optimizing the capacity of the buffer bin: Ensuring that the material level in the buffer bin is maintained at a certain level allows for a continuous and stable feed of material into the crusher, improving the overall efficiency of the production line. Additionally, real-time monitoring of the crusher's operation status and production data, such as power consumption, material level, and product particle size, enables timely adjustments to production parameters and equipment conditions based on the monitoring results.

BORGERS

"Take care of your equipment anytime, anywhere. If you need more information, you can also contact our service."