Daily Lubrication Tips for Borgers Feeders

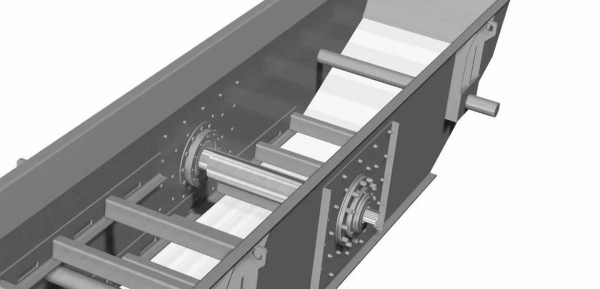

Dec 06, 2024Regular lubrication of feeders is an important process of daily maintenance. Proper lubrication of feeders plays a key role to avoid malfunctions, reduce wear rate, and extend the service life of the feeders. Below 2 lubrication tips for Borgers feeders for your reference.

1.Select right oil and use proper oil consumption

The daily maintenance of Borgers feeders requires lubrication oil, and we recommends using below oil with lithium or other similar models:

|

Brand |

Model |

|

BP |

Energrease LS-EP2 |

|

ESSO |

Beacon EP2 |

|

MOBIL |

Mobilux EP 2 |

|

SHELL |

Alvania Grease EP 2 |

|

SKF |

LGEP2 |

Lubricating oil consumption under different working conditions of equipment:

|

Normal condition Lubricating oil consumption for each bearing(g) |

Dusty condition Lubricating oil consumption for each bearing(g) |

|

150-200 |

50-70 |

*It's important to note:

① An appropriate lubricating oil consumption should occupy 30% - 50% internal space of the bearing. Excessive lubricating oil will shorten the service life of bearings.

② Must not mix different brands of lubricating oil.

For main motor, our recommended lubricating oil is below:

|

Brand |

NGL1-n°1 |

|

Mobil |

Polyrex EM |

2.Pay attention to bearings and take care of them frequently

In the daily operation of equipment, we need to regularly check the lubrication situation of bearings, such as whether the bearings can rotate freely, whether the temperature is normal, or whether there is oil leakage, etc., to detect and solve potential problems in time, ensure the smooth operation of the bearings, and extend their service life. We need to pay attention to below 5 points.

Take care of your feeders and other matching tracked jaw crushers or impact crushers or other equipment anytime, anywhere. For more information, you can contact your local dealer or Borgers service team.