It is widely used in industries such as sand and gravel, construction, road building, mineral processing, chemistry and so on. It can be used for sand making or for medium crushing and fine crushing of moderately hard ores. The processed materials include river pebbles, granite, basalt, etc. The maximum feed size is 35 mm, and the finished product particle size is less than 4.75 mm.

Payment :

TT or L/C at sightProduct Origin :

ChinaColor :

Yellow+Dark GreyShipping Port :

Shanghai PortWeight :

68000kgsModel :

BGI320RSBrand :

BorgersTransport Dimensions :

20800*3900*3800mmFeature:

l Fully automatic variable frequency feeding ensures the crusher maintains high crushing efficiency at all times

l Dual-motor drive provides stronger extrusion force on the roller surface

l With a tracked mobile design, it is flexible and convenient to transition, and can be quickly put into production with simple debugging

l Using hydraulic adjustment of the roll gap ensures convenience and safety

l The roller surface, featuring alloy steel inlaid with hard alloy studs boasts a longer service life

l Integrated design of each functional part, with four access ports for easy maintenance

l Precise lubrication management, extends the lifespan of bearings

l Simple structure, low breakdown rate, easy to maintain

l It could be designed as mobile tracked sand-making machine, modular sand-making machine or wheeled sand-making machine based on your demand

l Less powder rate, more sand production rate comparing to the vertical sand making machine

l Less wear parts cost due to squeezing working principle comparing to the vertical sand making machine

Specification:

Model | Max. Feed Size | Max. Capacity | Roller Size | Drive | Power | Weight | Transport Dimension LWH |

BGI320RS | 35mm | 150tph | 900*600mm | Electric-drive | 380kW | 68000kgs | 20800*3900*3800mm |

1.Hopper 2. Feeding conveyor 3. Crusher 4. Main Conveyor 5.Recirculation Screener 6. Transition Conveyor 7. Recirculation Conveyor

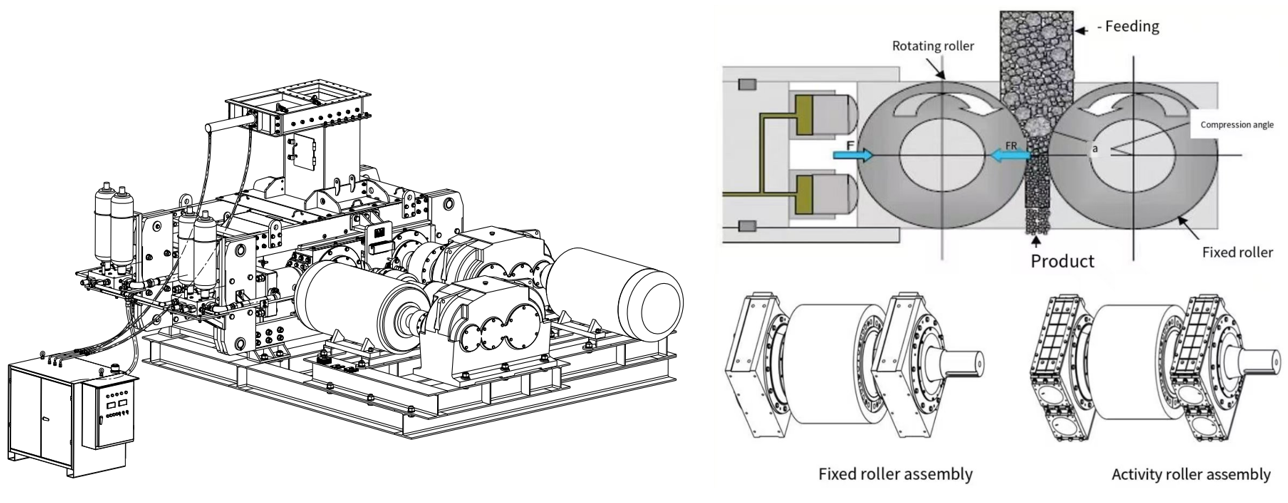

Crusher Working principle:

The main body of the high-pressure grinding roll crusher consists of two rollers that rotate in opposite directions. Materials are fed into the feeding device of the roller press by the conveying equipment, and enter between two rollers of the same size that rotate relative to each other. The material is pulled into the gap by the rollers, pressed into a dense material cake, and falls from the gap. It is then discharged from the hopper and output by the conveying equipment. Further dispersion or grinding of the material cake is carried out in the next process.

Innovation

Keeping things simple to operate and maintain by using high technology at the lowest possible costs.

Nothing stays the same, everything changes and so do our products. We simplify, perfect

and optimize over and over again by using high quality components and designs.

After Service

Servicing your Mobile roller Sand Making Machine is important, Borgers’s after-service team and its dealers will response within 12 hours

Tags :