Flip flop screens, also well known as high frequency vibratory screen, is designed to handle wet,sticky and other difficult materials that conventional screen clog or stick.It works with the combination of a double vibration principle and a flexible polyurethane-type screen media. The dual-vibratory forces work to apply linear acceleration to the materials traveling across the screen. Vibrations are simultaneously applied to the elastic screen, which rapidly stretches and relaxes. The stretching and relaxing of the screen transfers energy to the material, causing it to “jump” or “pop”. This secondary vibration, in turn, enhances the separation of materials.

Payment :

TT or L/C at sightProduct Origin :

ChinaColor :

Yellow+Dark GreyShipping Port :

Shanghai PortWeight :

depends on selected configurationModel :

BGCZS1548Brand :

BorgersTransport Dimensions :

Container transportant,depends on selected configurationFeatures

Ø A wide range of application, municipal solid waste processing, coal,valuable minerals like gold ore, natural riverbed sand and manufactured sand.

Ø High screen efficiency.

Ø Easier to maintain.

Ø Wear resistant for the second-deck polyurethane screen,durable, less prone to blinding.

Ø Simple to replace,reduce down times and mitigate ongoing maintenance costs.

Specification

|

Model |

Decks of Screen |

Max. Feed Size |

Screen Size |

Max. Capacity |

Angel of Screen(°) |

Amplitude |

Motor Power |

Vibration Frequency |

Weight |

Transport Dimension LWH |

|

BGCZS1548 |

2 |

300mm |

1550*4860mm |

100-200tph |

20 |

10-12 |

Electric or Hydraulic 15kw |

750rpm |

depends on selected configuration |

5260*3350*3010mm |

|

BGCZS2470 |

2 |

300mm |

2400*7000mm |

200-300tph |

18 |

10-12 |

Electric or Hydraulic 37kw |

750rpm |

depends on selected configuration |

8090*4590*7290mm |

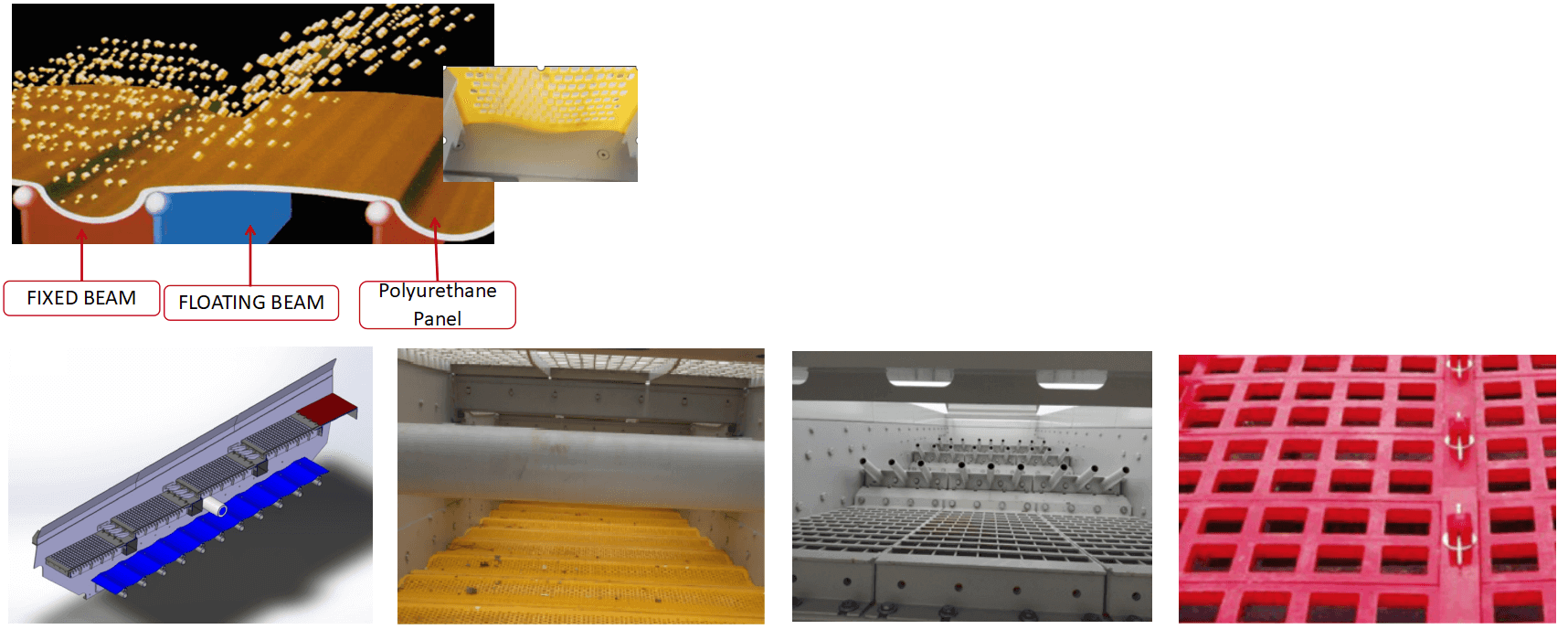

Flip-Flop Principle

Wear-resistant and elastic polyurethane tensioned panels are installed on the fixed and floating crossbeams of the tensioning structure. When the screen box performs circular motion,the tensioning structure's floating crossbeam moves back and forth relative to the fixed crossbeam through the action of special shear rubber.This movement drives the polyurethane screen mesh to alternate between tension and relaxation, thereby achieving the screening process.

The tensioning motion of the elastic tensioned screen panels allows the screen surface to obtain a higher acceleration (much greater than the adhesive force of the material), preventing material from sticking to the screen surface. This ensures that the material is thoroughly loosened and rapidly stratified. The tensioning motion of the screen panels, combined with their flexibility, causes slight dimensional changes (similar to the "breathing" effect of a screen) in the opening direction under tension. This prevents critical particles from clogging the screen openings, resulting in a higher passing rate for fine particles.

Details Photos

Innovation

Keeping things simple to operate and maintain by using high technology at the lowest possible costs.

Nothing stays the same, everything changes and so do our products. We simplify, perfect

and optimize over and over again by using high quality components and designs.

Your choice of Drive

As fuel and energy costs are playing more and more important effect on operational costs, Borgers offers electric and hydraulic drive system for your choice.

which ensures a minimum impact on the environment and maintenance and operating costs are considerable lower.

After Service

Servicing your equipment is important, Borgers’s after-service team and its dealers will response within 12 hours

Tags :