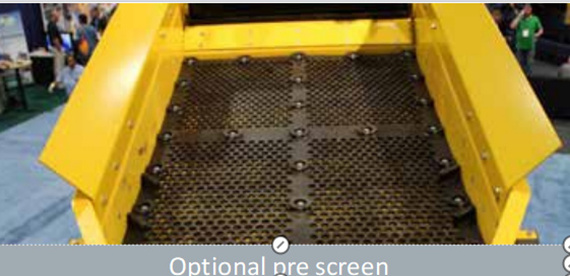

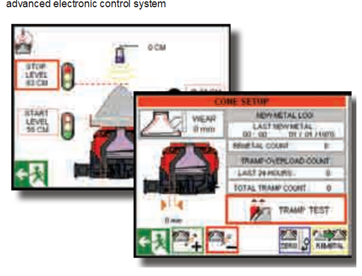

The Borgers BGC2390 is tracked mobile cone crusher drive by direct drive.The cone features variable speed drive, hydraulic tramp relief system and ability to change closed side setting while crushing. The large hopper/feeder has an automated metal detection and a purge system to protect the cone and reduce downtime by removing metal contaminants via the purge chute.

Payment :

TT or L/C at sightProduct Origin :

ChinaColor :

Yellow+Dark GreyShipping Port :

Shanghai PortWeight :

63000 kgModel :

BGC2390Brand :

BorgersTransport Dimensions :

18800*3100*3500mmFeatures:

Specification

|

Model |

Cone Chamber |

Max. Feed Size |

Max. Capacity |

CSS RANGE |

Drive |

Engine Power |

Weight |

Transport Dimension LWH |

|

BGC2260 |

1000mm |

160mm |

260TPH |

16-34mm |

Hydrostatic |

Cat C9/261 |

38300 kg |

16900*2800*3500mm |

|

BGC2260RS |

1000mm |

160mm |

260TPH |

16-34mm |

Hydrostatic |

Cat C13/328 |

40600 kg |

16800*2800*3500mm |

|

BGC2390 |

1300mm |

220mm |

390TPH |

20-40mm |

Directly drive shaft |

Cat C15/390 |

63000 kg |

18800*3100*3500mm |

|

BGC2260E |

1000mm |

160mm |

260TPH |

16-34mm |

Electric,Plug-in |

Perkins/74.5 |

45600 kg |

18300*3000*3800mm |

Process knowledge

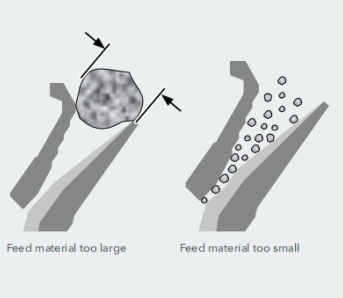

The correct feed size greatly influences the crushing result, the wear and output of the cone crusher.

If the feed material is too large, the feed behaviour is not ideal and the crushing capacity is reduced.

Crushing then takes place above the actual crushing zone of the tool, which leads to increased and uneven wear.

In the worst case, ringbounce can occur.If the feed material is too small, the power of the crusher is not adequately

used and the final product quality suffers. Partialwashout develops on the crushing tool, which leads to a reduction in the crushing capacity and a shorter service life of the crushing tool.Fines in the feed material must generally be avoided.Rule of thumb: the supplied content of fines of 0-5 mm shouldnot exceed 5 %!

Details Photos

|

|

|

|

Photos at job site

Innovation

Keeping things simple to operate and maintain by using high technology at the lowest possible costs.

Nothing stays the same, everything changes and so do our products. We simplify, perfect

and optimize over and over again by using high quality components and designs.

Your choice of Drive

As fuel and energy costs are playing more and more important effect on operational costs, Borgers offers two drive system for your choice.

One is Diesel hydraulic version, which will be more easy for continuous movement. In order to save fuel and energy costs, we designed Fuel Saving Load sensing technology, which is an advanced Diesel engine with low emission norms

Combined with a load sensing hydraulic system which ensures a minimum impact on the environment. Normally, Using load sensing hydraulic systems reduces the fuel usage with 25%.

Another is Electric, hybrid & plug-in version, which could be connected to electrical grids.Maintenance and operating costs are considerable lower.

After Service

Servicing your equipment is important, Borgers’s after-service team and its dealers will response within 12 hours

Tags :