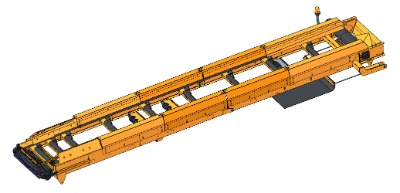

Borgers 4200 combines the functions of scalping, screening and stockpiling into the one integrated mobile unit. Its rugged design for screening materials such as sand and gravel, topsoil or aggregates. Standard features include a variable speed belt feeder, remote tipping reject grid, hydraulic screen angle adjustment, and three on-board stockpiling conveyors.

Payment :

T/TProduct Origin :

ChinaColor :

Yellow+Dark GreyShipping Port :

Shanghai PortWeight :

31000kgsModel :

BGS4200Brand :

BogrgersTransport Dimensions :

10309*2632*3480mmSpecification

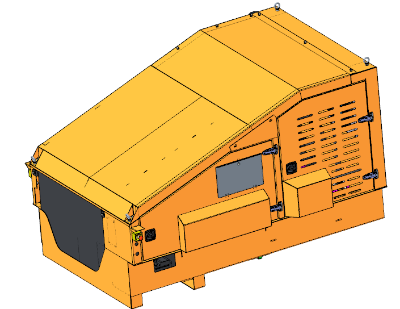

Engine

Yanmar 4TNV98CT-NIY 53.7kW Tier4

Hopper

Hopper capacity: 4.0m3

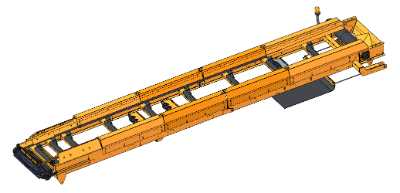

Feed / Main Conveyor

800mm wide variable speed belt feeder

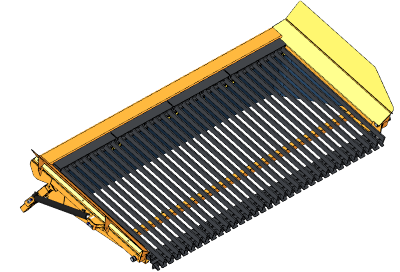

Grid

102mm remote control hydraulic tipping reject grid

Grid opending 2.95*1.46m

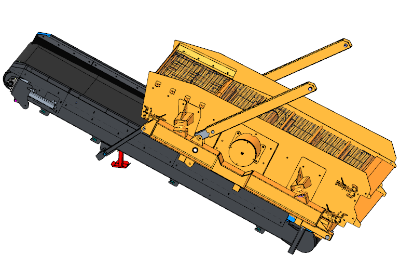

Screenbox

2.44m x 1.22m 2 deck incline screen

Grease filled 4 bearing screenbox

End tensioned decks

Hydraulic screen angle adjustment: 25° - 35°

Finesize - Tail Conveyor

1050mm (42”) wide plain belt

3.35m stockpile height (to drum centre)

General

Access catwalks to both sides and around top of screen

Heavy duty undercariage unit with 400mm wide tracks

Control operation of tracks via hand-held set with 5m connection

Low level greasing

Emergency stops (4 nr)

Applications

Aggregate Recycling Mining Sand&gravel Topsoil Processed ores Blastedrock C&Dwaste Processed minerals River rock Composted materials

Features & Benefits

Ø High capacity up to 200 tph (depending on feed size, mesh size & material type)

Ø Maximum feed size 150mm

Ø Engine protection shutdown system

Ø Heavy duty single shaft incline screenbox with adjustable angle

Ø Screen mesh access system for quicker mesh changes

Ø Removable heavy duty pendant remote control system

Ø High performance hydraulic system - cast iron pumps & motors complete with hydraulic cooler

Ø Low profile double deck vibrating grid option with radio remote control tipping grid rams, angle adjustable & fully riveted construction

Ø

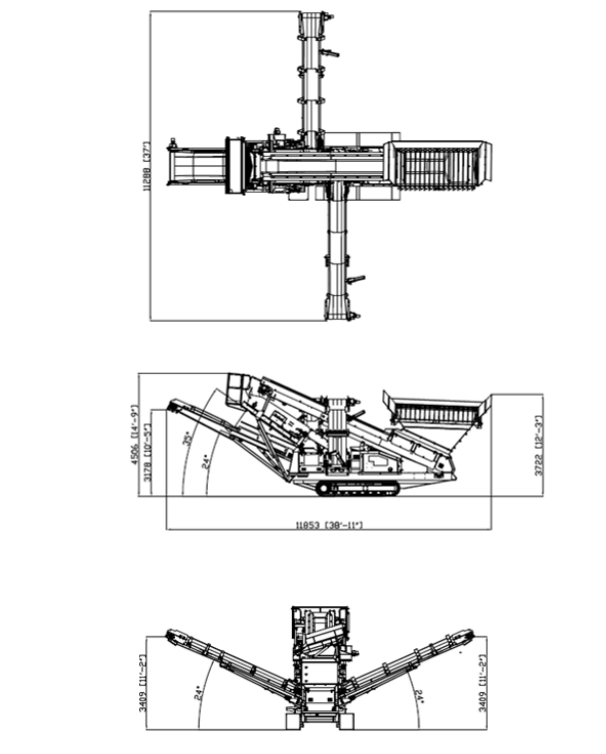

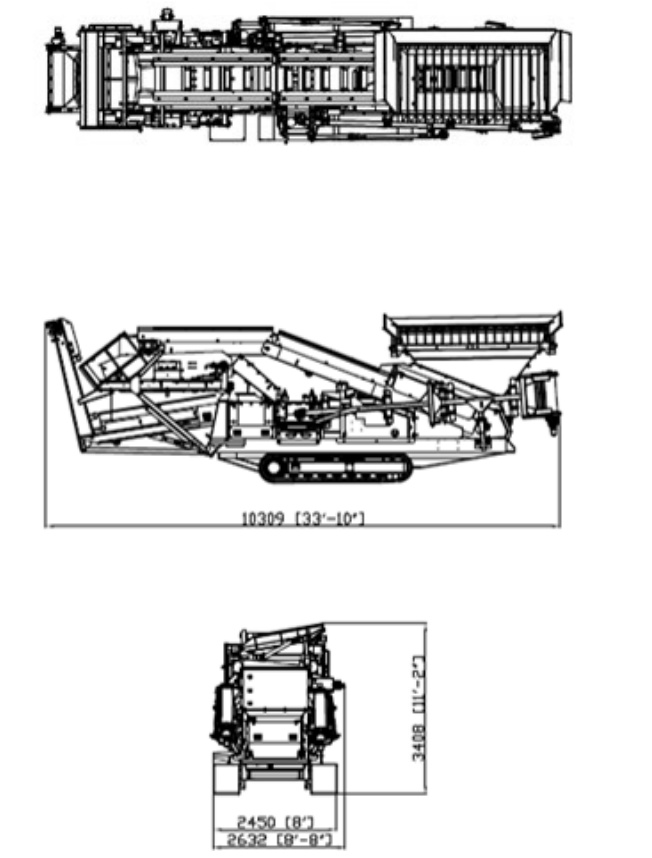

Hydraulically folding conveyors for transport

Working Dimensions

Transportation Dimensions

Tags :