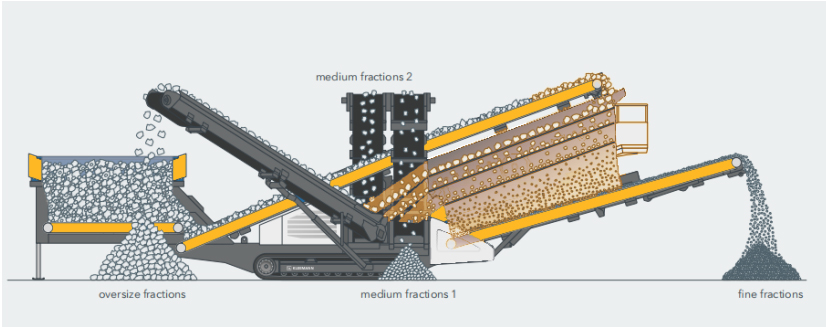

The Borgers BGS500E is the industry’s leading tracked mobile screen. To realise and appreciate the constant change of market demands and ever increasing environmental factors with resultant impacts, the BGS500E has been designed to deliver maximum efficiency and increased flexibility for all markets.

While the unit continues to be fitted with a world famous brand water-cooled engine, 97kW as standard, an additional 2 * 37kW Electric motors are fitted to allow power source from an electrical supply when in operating mode.

This optional feature catapults the BGS500E into a class of its own for many existing and new applications by ensuring optimal power sources can be chosen to suit each customer’s specific requirement to gain maximum profitability and efficiency from their screening and separation system.

This system has been designed to ensure operation at high altitudes (above 1500m), where there is a lack of diesel quality, or simply where electricity costs in some regions are lower than equivalent diesel costs, so allowing the most efficient method to be incorporated in the screening process

Payment :

TT or L/C at sightProduct Origin :

ChinaColor :

Yellow+Dark GreyShipping Port :

Shanghai PortWeight :

BGS500EModel :

BGS500EBrand :

BorgersTransport Dimensions :

19300x3000x35000mm

Features:

Ø Power consumption reduced by up to 50% in some regions than the standard diesel/hydraulic configuration.

Ø Maximum utilisation and efficiency in altitudes 1,500m above sea level.

Ø 2 * 37kW electric motors coupled to Hydraulic pumps that can provide for all the operating hydraulic needs of the plant.

Ø The on-board electric control panel can be connected to 380-415V 50Hz 3 Phase Grid or Generator Power.

Ø User friendly electrical connection and control system with safety interlocks to ensure the engine cannot be operated when the motors are running and vice versa.

Ø The tracking system is disabled when operating with mains power to protect operators from potential risks of tracking the machine when a live cable is connected.

Ø All electrical components are dust and water proofed, and the additional electrical components are positioned within the Powerunit control cabinet for security and convenience.

Specification

|

Model |

Max. Feed Size |

Max. Capacity |

Screen Size |

Engine Power |

Weight |

Transport Dimension LWH |

|

BGS500 |

150mm |

500tph |

1520*6100mm |

Cat C4.4/97 |

32000kg |

19300*3000*3500mm |

|

BGS275 |

500mm |

275tph |

1530*3600mm |

Cat C4.4/83 |

25000kg |

14400*3000*3300mm |

|

BGS500E |

150mm |

500tph |

1520*6100mm |

①、Cat C4.4/97 ②、Electric,Plug-in -74kW |

40000kg |

19300x3000x35000mm |

|

BGS9800 |

250mm |

800tph |

1930*6100mm |

Cat6.6/151 |

43000kg |

18900*3000*3500mm |

Photos at job site

Innovation

Keeping things simple to operate and maintain by using high technology at the lowest possible costs.

Nothing stays the same, everything changes and so do our products. We simplify, perfect

and optimize over and over again by using high quality components and designs.

Your choice of Drive

As fuel and energy costs are playing more and more important effect on operational costs, Borgers offers two drive system for your choice.

One is Diesel hydraulic version, which will be more easy for continuous movement. In order to save fuel and energy costs, we designed Fuel Saving Load sensing technology, which is an advanced Diesel engine with low emission norms

Combined with a load sensing hydraulic system which ensures a minimum impact on the environment. Normally, Using load sensing hydraulic systems reduces the fuel usage with 25%.

Another is Electric, hybrid & plug-in version, which could be connected to electrical grids.Maintenance and operating costs are considerable lower.

After Service

Servicing your equipment is important, Borgers’s after-service team and its dealers will response within 12 hours

Tags :